The Revolution of Electronics Recycling: Garner Products Leading the Way

In the realm of electronics recycling, there exists a stark contrast between popular perception and harsh reality. While many envision a seamless and environmentally-friendly process, the truth is much bleaker – shredding. Shockingly, less than 20 percent of electronic waste (e-waste) actually undergoes recycling, with the majority destined for the shredder in search of raw metal extraction. This revelation sheds light on a pressing global issue that demands innovative solutions to mitigate further environmental degradation.

The DiskMantler: A Technological Breakthrough

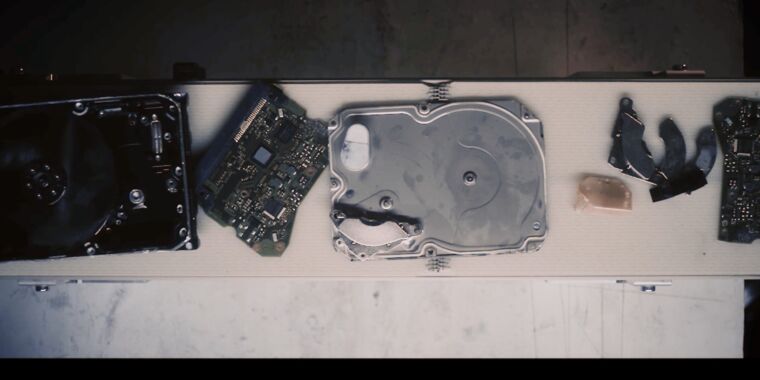

Enter Garner Products, a renowned data elimination firm, with a ground-breaking invention – the DiskMantler. Designed to address the inefficiencies of traditional recycling methods, this cutting-edge machine boasts the capability to process 500 hard drives per day. Unlike conventional approaches that consign hard drives to a fate of obliteration, the DiskMantler disassembles these devices with precision, segregating valuable components for potential reuse.

The modus operandi of the DiskMantler entails subjecting hard drives to relentless vibrations, thereby disintegrating them into essential parts within a mere 8-90 seconds. Particularly noteworthy is its ability to dismantle welded helium drives in approximately two minutes, showcasing unparalleled efficiency rooted in scientific principles. Drawing inspiration from the pioneering work of Gerhard Junker, a distinguished German scientist, the DiskMantler leverages vibrations to effectively loosen screws and fasteners, unlocking a realm of possibilities for sustainable recycling.

Sustainability and Rare-Earth Magnet Recycling

Moreover, the advent of the DiskMantler extends far beyond mere component recovery, with profound implications for rare-earth magnet recycling. While current methodologies involve energy-intensive processes to break down rare-earth magnets into elemental form, Garner’s innovative approach holds the promise of direct magnet reuse. This paradigm shift not only minimizes extraction requirements but also diversifies the global supply chain, fostering a more resilient and sustainable future for the electronics industry.

Embracing this vision of sustainability, HyProMag, a Canadian firm, pioneers a University of Birmingham-patented process to reclaim drive magnets directly from hard drives. By leveraging robotics to extract these magnets and diverting residual components for recycling, HyProMag exemplifies a circular economy ethos that redefines conventional recycling practices.

Looking Ahead: A Brighter Future for Electronics Recycling

Although the landscape of electronics recycling is rife with challenges, the collaborative efforts of industry leaders like Garner Products and HyProMag herald a promising future. As technological advancements continue to revolutionize recycling processes, the prospect of a more efficient, eco-conscious, and sustainable industry looms on the horizon. With a steadfast commitment to innovation and environmental stewardship, these pioneering firms inspire a new era of responsible e-waste management.

Image/Photo credit: source url